News

What it Takes to be a NASA Contractor

As NASA wound down the Space Shuttle Program and began to ramp up its Artemis Program while continuing to service the International Space Station, the space agency began to look to commercial companies to provide not only engineering expertise but hardware development as well. Since the announcement of the first commercial partnerships in the mid-2000s, more companies have been afforded the opportunity to contribute to the U.S. space program. From robotic missions to Mars and the Moon, to advanced in-space manufacturing technologies, being a part of NASA’s space exploration can be the pinnacle of an engineering company’s experience. In the past decade, Motiv Space Systems has worked to contribute to the success of American space exploration as a contractor for NASA and other organizations.

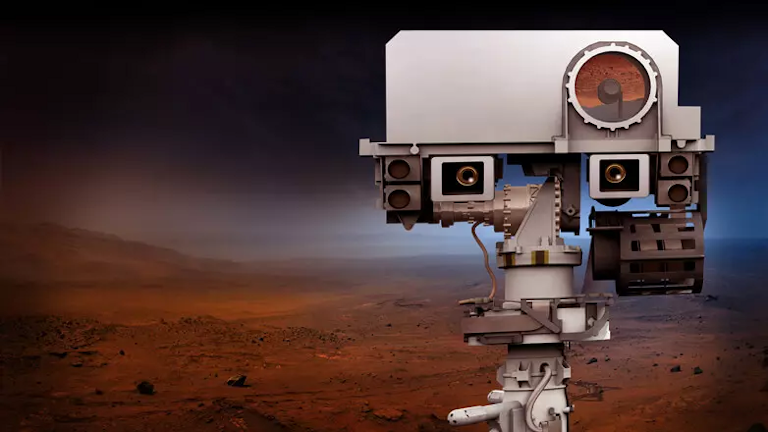

To-date, Motiv has contributed to some of NASA’s most high-profile exploration missions. The successful 2020 Mars Perseverance Rover mission relies on a robotic arm engineered by Motiv. The arm has been used to collect samples, which will one day be returned to Earth. Other Motiv mechanical systems are enabling the first-ever zoomable camera on the surface of another planet.

Motiv contributed to the success of NASA’s 2020 Mars Perseverance Rover mission.

To meet the needs of the Artemis Program, NASA’s return to the Moon, Motiv is working with NASA-JPL on the deployment of robotic systems capable of operating at -180℃, without the need for additional heaters or special electronics. The COLDArm will enable astronauts at the lunar south pole to continue operating, even during the 14 days when the sun will not be visible.

Motiv also contributes to future capabilities in Earth orbit. NASA has long been known for its advanced engineering objectives, and the two on-orbit servicing, assembly, and manufacturing (OSAM) missions are no exception. Motiv is providing mechanical systems to enable on-orbit manufacturing of a solar array, demonstrating technology that will help reduce the cost of future space exploration.

The development of space-rated motor controllers has played a pivotal role in Motiv’s contributions to NASA and other organizations. These controllers are the heart of the engineering systems developed by Motiv. Using these controllers, Motiv has provided NASA with key components for the 2020 Mars Perseverance Rover, and continues to work with the space agency on new technology demonstrations.

NASA-JPL’s engineers worked closely with engineers from Motiv on the development of COLDArm.

The engineering capabilities at Motiv are only a piece of what the company has to offer NASA. Being able to design advanced space hardware is one thing, but being able to manufacture that same hardware is another. With a class 10,000 clean room, in-house machine shop, class 100 assembly and test stations, and operational thermal testing facilities, Motiv can produce the engineered robotic and mechanical systems at a facility in Pasadena, CA.

Being a contractor for NASA and contributing to the future of America’s space exploration – both robotic and manned – is something that Motiv Space Systems does not take lightly. Pouring decades of combined engineering experience into the design of these advanced mechanical systems is all part of the job that culminates in seeing the images returned from Mars or the solar array manufactured in Earth orbit.